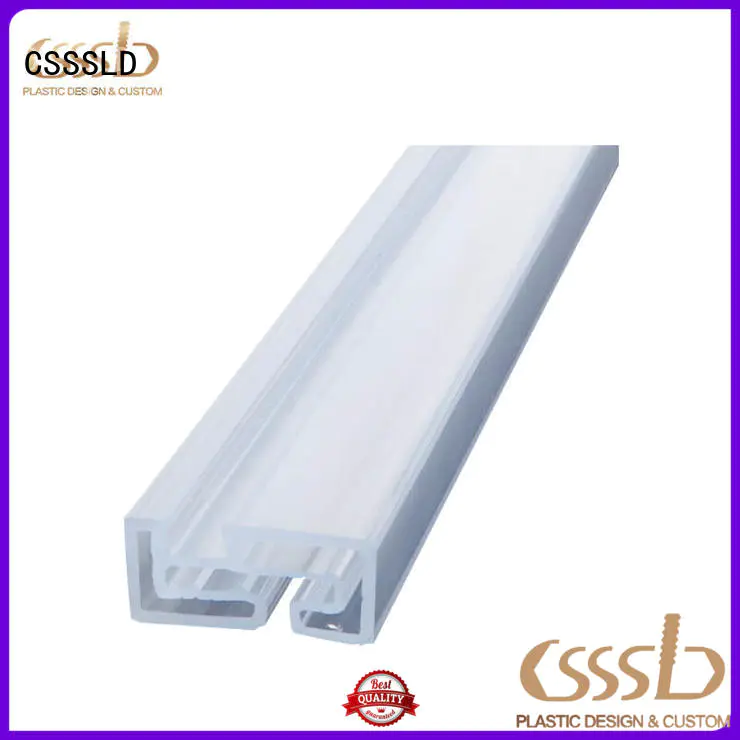

Product Name:Fluorescent Light Diffuser Cover

Description

Our company is a leading company in the extrusion and co-extrusion of plastic profiles.We offer our customers vast experience and versatility in designing and manufacturing dedicated solutions and custom projects as well as a complete catalogue with over 5,000 solutions ready for application in all kinds of industrial and decorative projects.

Our comprehensive production process allows us to adapt raw materials to the requirements of each project with our own formulations of plastics and colorants, mould design and construction, special finishes and flexible production lines that greatly reduce new product launch lead times.

Our technological background adds value to our customer relations, thanks to our capacity to innovate and solve technical challenges by adapting standard processes to specific needs.

Our Services

We offer our customers an extensive catalogue which includes custom made solutions, mould design, engineering, extrusion and co-extrusion, R&D,raw material and colorant formulating and special finishes. Our comprehensive production process enables us to address any need or Project with exacting technical requirements. We draw on our vast experience to develop dedicated projects using imaginative, effective applications from several sectors to adapt commonly used processes to the special needs of our customers. We rely on our own facilities to develop our comprehensive design and production process, including mould design using electro-erosion as well as mould maintenance and safekeeping.

We offer a complete process from raw material to final quality control.

We adapt market-ready raw materials, formulations and colorants in our laboratory, where we work with all kinds of plastics, from conductive to biodegradable, in a constant search for new solutions that includes collaborating with different research programmes. Our thirty production lines of different sizes and technologies enable us to quickly initiate all kinds of production runs and projects.

Engineering Solutions

We like to specialise and thrive on challenges. That’s where we put our engineering solutions to the test, offering customers in any sector our solutions to specific requirements with techniques that had previously been untried or ineffectively applied.

We know how to apply common construction techniques to decoration needs, or implement raw materials and processes commonly used for signage in lighting projects. Or the other way around, or even combining any of our areas of expertise.

Our extensive background in all kinds of projects and technologies produces reliable results. At Polinter we believe this sets us apart and we are proud of our technical expertise, which is one of our most valuable assets.

Many times, the most practical and imaginative solutions are able to address the seemingly most complicated technical challenges. Our ability to implement proven technical processes from other sectors is an added value bonus we can offer our customers.

Mould design and construction

Essential to us are moulds, the basic elements in the extrusion and co-extrusion process. Together with other raw materials and colorants, they are an important part of the comprehensive design and manufacturing process at our facilities in China.

We design and manufacture in on-site facilities nearly all of the moulds used in our projects for several reasons. In the first place, to develop and improve our own technology. Our experience, specialization and technological expertise come from decades of work on projects in diverse sectors. We also incorporate the latest technologies and models available on the market according to project requirements

We also strive to develop moulds and make adjustments quickly to suit customer needs. Our in-company development means we can see to it that time-sensitive changes and strict delivery deadlines are met. We guarantee agility in this part of the process so that orders can enter the production stage as quickly as possible.

Our specialised staff uses state-of-the-art machinery and CAD-CAM programmes in the initial design stage and electrical discharge machining tools in the construction, adjustment and quality control of our moulds.

Special finishes

Adding value to the product by applying specific processes and finishes is a market requirement. We provide a wide range of solutions, many of them based on our own patents, to personalise any type of profile suited to many sectors, from construction to interior design. The widespread use of plastic profiles with specific needs requires this flexibility.

The company has several exclusive patents. Our decorative profile “Decoform” is used in interior design to gives profiles a specific color, look and texture. Another Polinter patent, the “Novocrom” finish, provides laminated profiles with greater strength and resistance.

“Stilkrom” is a highly weather resistant profile with a metallic interior for application in automotives, signing and furniture, both on decorative and functional profiles.

Special finishes can be used in a wide variety of applications, and include abrasion and scratch resistant metallic effects, vinyl woodgrain, adhesives and Offset printed profiles according to customer needs and product application.

Other operations and tooling processes we perform on our profiles and tubes include cutting to specific length, machine pressing, drilling and adhesive bonding. The final packaging guarantees that our products reach the customer in perfect conditions after shipping and handling.

We have an extensive background in formulating the different types of PVC used in all the production processes we carry out. Our laboratory formulates the raw materials and colorants and introduces modifications and improvements to the technical plastics available on the market that are used in several projects.

Our know-how in adapting raw materials to the specific needs of each sector ensures our customers flexibility and competitiveness. A specialized division quickly prepares raw materials using grinding, dosage and weighing equipment, and our fully-equipped laboratory can precisely adjust formulations with all kinds of materials testing and trial runs.

The same processes are applied in the colouring of plastics. For our customers, the combination of developing and adapting raw materials and colorants greatly enhances the scope for introducing specific solutions. Our offer of products and services greatly exceeds that of many companies in the sector.

We always match the most suitable materials when catering to the needs of the different sectors we do business in. Among other materials, we work with rigid and flexible PVC, ABS, Polyolefins (PE, PP, EVA, etc.), PC, PMMA, PA6, PA12, PVDF, SBS, SEBS and PS.

In the lighting sector, our activity focusses on Diffusers, Tubes, LEDs and all kinds of custom designed plastic products according to customer specifications for the required lighting project, with original designs and the best technical performance.

We develop all kinds of geometries and materials according to current market trends that require resistance to aging, high transparency, high quality finishes, etc., which give added value to the final product they complement.

Applications

DIFFUSERS | LEDs |

Exterior | Display units |

TUBES | DESIGNS |

| Decorative Colored Two-zone Security lights Fluorescent lights Support structures | Architectural Ornamental Bathroom lighting Strip lighting Electric tracks According to specifications |

All our profiles are manufactured to obtain the best photometric performance with the most suitable material, geometry and surface design.

We provide our customers with product design assessment to comply with or exceed the IP and IK rating of their light fixtures. Our commitment focusses on obtaining the most adequate mechanical properties, temperature resistance, transparency, light transmission and UV resistance, as well as excellent overall design.

TABLE OF LIGHTING PROFILES

PROFILE

|

DIMENSION |

MATERIAL |

FINISH

|

DIFUSSER

| Wide range of models available | PC-Polycarbonate | Transparent |

TUBE

| Several lengths available up to 150 mm in diameter | PC-Polycarbonate | Transparent |

LEDs

| Several solutions available | PC-Polycarbonate | Transparent |

DESIGN

| According to drawings or requested specifications | PC-Polycarbonate | Transparent |

Glass partitions

We provide plastic profiles to all sectors that work with glass partitions, shower enclosures, and dividers.

We have an extensive background in this industry, which has specific demands regarding functionality, efficiency and material resistance, and apply solutions from our catalogue and our technical and production capacities to customer projects to produce profiles that meet their exacting standards of transparency and finishes.

This sector is in constant evolution, so our offer includes new models of profiles for market demands, including rigid, flexible and co-extruded products, U and H shaped profiles, joints and other profiles suitable for use in all kinds of applications.

We use the best material for each project, including thermoplastic products such as PVC, PC, ABS, PE, PP, etc., with transparent, opaque, weather and UV resistant, textured, smooth or adhesive-free finishes. Some of our exclusive standards include “Decoform” and “Novocrom”.

Three factors define the quality grade of our products – functionality, transparency (on glass partitions) and UV resistance (on outdoor applications). Our capacity to formulate and combine the most suitable raw materials enables us to provide our customers with profiles that satisfy these basic characteristics and at the same time are also flexible and resistant to impact and pressure.

Our involvement in this kind of solutions goes beyond plastic profile development. We provide finishes that increase the functionality of many sophisticated projects, from gliding surfaces and decorative elements to magnetic applications.

We also provide the bath sector with special colours, custom surface treatments, glossy enamels, chrome and mat aluminium, as well as applications using WPC profiles.

We apply specific solutions to the sector by combining the products in our catalogue with other materials found in different industrial applications with proven effectiveness. For special needs, we develop new solutions in our tooling and materials divisions.

Dimension According to customer's drawing.

1.Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2 Steel:C45(K1045), C46(K1046),C20

3.Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

Materials Available 4.Bronze: C51000, C52100, C54400, etc

5.Iron: 1213, 12L14,1215

6.Aluminum: Al6061, Al6063

7. OEM according to your request

Products Available Lamps and lanterns , Auto parts, Machinery parts and kitchenware and so on.

Surface Finish annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, yellow passivation, gold passivation, galvanizing, satin, etc.

Processing Method Deep draw , spinning, bending, stamping ,cnc machining, turning, milling, drilling, grinding, broaching, elding and assembly.

1. Competitive price with good quality

2. Low MOQ (100pcs is even acceptable in some special conditions)

Advantages 3. Short lead time (7-30days according to order qty)

4. Customized size and spec /OEM available

Package Suitable for sea and air transportation or as required

Certificate ISO9001:2008, TS16949

Lead Time 10days to 40 days according to order qty.

Changshu Shunlida Plastic Product Factory

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist